We re-engineer cars for your security

We are located in Liège, Belgium – well-known for its steel industry and craftmanship.

We jointly work with ballistic specialists, laboratories and European manufacturers. They are recognized as producing today’s highest quality transparent (glass) and opaque (body) armouring materials. Our house provides vehicles that effectively address today’s evolving complex ballistic and explosive threats.

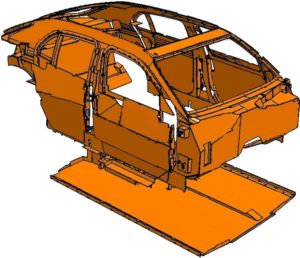

We apply these armouring solutions into a “survival cell” within the original body of the car. This process is unique in the automotive industry. This armoured shell becomes the main structural component dramatically increasing the strength.

This unique method also includes an elaborate system of overlaps insuring there are no ballistic gaps through which a projectile may penetrate.

EVOLVING THREATS

Worldwide security experts agree that today a major threat comes from explosive attacks whether improvised explosive devices (IED’s) or the more classic hand grenades (i.e. DM-51 or equivalent).

The Carat armored shell provides the ultimate protection against these threats as it shares and absorbs the blast while the transparent armor is firmly retained by bullet proof frames.

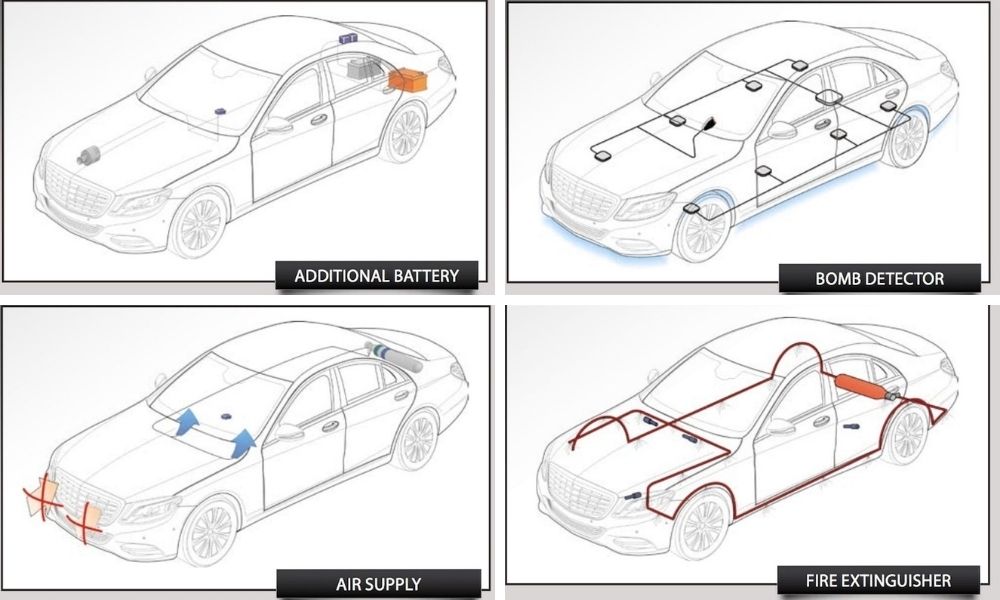

SECURITY EQUIPMENT

A wide range of security equipment are included in the armor conversion or are available as options : self-sealing fuel tanks, wheel assemblies with runflat capabilities, multiple protected battery systems, automatic fire extinguishers, emergency air supply, etc.

Other safety material may be designed according to customers’ specific requirements.

TRANSPARENCY TOWARDS OUR CUSTOMERS & CERTIFICATIONS

Our customers are always welcome in our factory to inspect their own car during the production.

We even strongly insist to have it inspected at least twice :

- After wheel base extension and/or armouring and before re-assembly.

You can see which materials were used and how these were integrated. This is the best way to acquire confidence in the product that will protect your life. - After completion of the vehicle and before shipment.

You or your own experts can test drive it.

We’re able to provide ballistic certificates issued by an independent and NATO approved laboratory, i.e. in Germany, The Netherlands, France… confirming the vehicle meets the required level of safety.

A precise conversion on 3D jigs

In close collaboration, the R&D department and the sheet metal workshop have developed 3D jigs. Any elongated and raised vehicle is placed on a jig where it will be cut. These are equipped with the body’s reference points, which makes it possible to extend the chassis and raise the roof with tolerances equal to those of the manufacturers. Once the modifications have been made to the body, the armoring can begin, always on jigs.

REINFORCED HINGES

The additional weight of armoured doors could cause doors to sag down and close with difficulty. To solve this issue, we have :

- designed reinforced hinges using high-strength steel

- integrated the armouring in all box-sections of the vehicle

- attached the door hinges directly on the armouring structure

The doors attached to the armoured structure and no longer to the original body will remain in correct position for lifetime of the vehicle.

Door stability is guaranteed even in case of extended rear doors armoured to level B7, weighting approx. 200 kg.

This technology is very important when it comes to long limousines such as long wheelbase Mercedes-Maybach.

REINFORCED SUSPENSION

Adapted to support the load :

As a result of the modifications made to the vehicle, it easily takes 1.5 to 2.5 tonnes more. The mechanical components must be adapted according to whether they are air and/or hydraulic suspension. The suspension elements are resized and reinforcements are added to the body. The car’s basic technology is respected and we retain options such as: sport suspension – comfort mode suspension or enhanced suspension.

For some off-road vehicles and given certain extreme constraints such as road conditions, we have developed dual suspensions with 8 shock absorbers and 6 springs.

A most cost-effective option that will significantly increase vehicle life, comfort and performance.